The 0.9mm Micro PLC Splitter package features 900um loose tube fiber protection on the input and output fibers and can be provided with a selection of connectors at fiber termination, making it suitable for use directly in distribution boxes or network cabinets.

Features of 0.9mm Micro PLC Splitter:

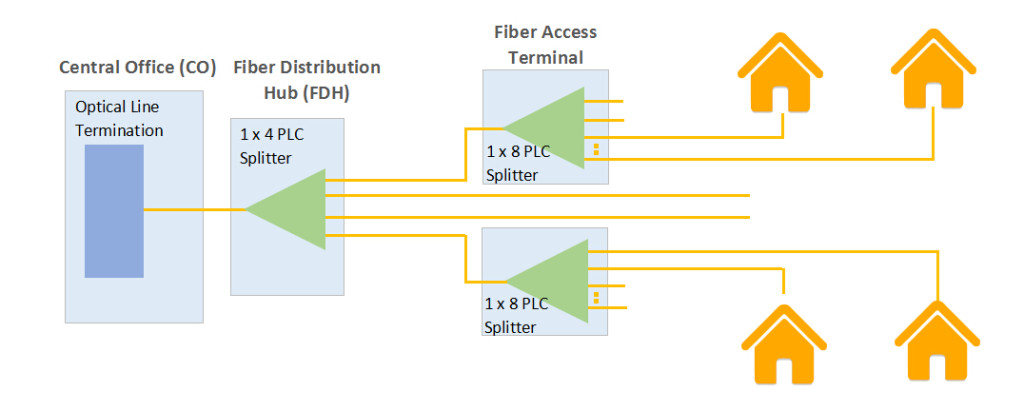

Application:

Q: What’s the difference between bare fiber PLC splitter and micro PLC splitter?

A: The main difference between a bare fiber PLC splitter and a micro PLC splitter is the packaging and the ease of installation. The micro PLC splitter(with connectors) is a more convenient and easier-to-install solution, while the bare fiber PLC splitter(No connectors) offers a more cost-effective option but requires more technical expertise to install.

Step 1: Consider the costs, performances & applications, and environments, choose which type of fiber optic splitter you’ll need, there are generally two types of fiber optic splitters: FTB Coupler and PLC Splitter.

FBT coupler is a fiber optic splitter made by fusing and stretching two or more optical fibers together to create a tapered region that splits and distributes the input signal between output fibers. FBT couplers are commonly used in fiber optic networks, but they have some limitations such as limited bandwidth and higher insertion loss.

PLC Splitter is highly preferred over the FBT splitter due to its numerous advantages such as its flexibility in working wavelength, high stability, low-temperature loss, and reduced failure rate. In recent times, PLC splitters are compact and can be integrated into small packages, making them ideal for use in optical communication systems where space is limited. There are several types of PLC (Planar Lightwave Circuit) splitters, which differ in terms of their design and functionality.

The difference between FTB Coupler and PLC Splitter

| Parameters | FBT Coupler | PLC Splitter |

| Operating Wavelength | 850nm, 1310nm, 1550nm | 1260nm -1650nm (full wavelength) |

| Application | CATV Systems, PON, FTTx Networks, etc. | CATV Network Systems, PON, FTTx Networks, etc. |

| Performance | 1×8 (can be larger with a high failure rate) | 1×64 (equal to all branches providing high reliability) |

| Branches Split Attenuation | Equal or unequal division, customized | Equal splitter ratios(non-customized) |

| Input/Output | One or two inputs with an output maximum of 32 fibers. | One or two inputs with an output maximum of 64 fibers. |

| Operation Temperature | -5 to 75℃ | -40 to 85 ℃ |

| Price | Lower | Higher than FBT Coupler |

| Summary | Used for simple signal splitting | Used for more complex and precise signal splitting in higher-capacity communication systems |

Bare fiber PLC Splitter

Micro PLC Splitter

ABS Box PLC Splitter

LGX Box PLC Splitter

Rack Mount PLC Splitter

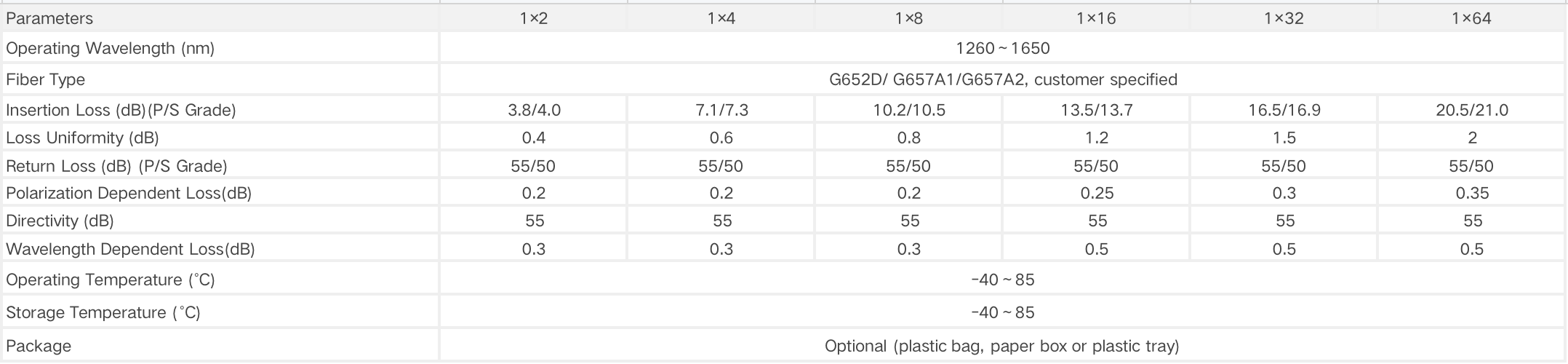

Specification of PLC Splitter

1xN PLC Splitter

2xN PLC Splitter

Step 2: Choose the right fiber type, The splitter should be compatible with the fiber type you are using, whether it is single-mode or multimode.

Step 3: Decide which Splitting Ratio you’ll need in your network: The splitting ratio determines how many outputs are needed per input. Common splitting ratios include 1:2, 1:4, 1:8, 1:16, 1:32, etc. Make sure to choose the appropriate splitting ratio based on your specific needs.

Step 4: Determine how many ports you require. Splitters are available in various configurations, ranging from one input and two outputs to one input and 64 outputs or more.

Step 5: Select the input and Output Connectors, the most common connector types are SC, LC, and FC.

Step 6: Choose the polish type of connectors. There are two types of connector polish, UPC and APC.

Easy shop

Professional Seller

Excellent Quality

Global Shipping

Fast Delivery

We will contact you within 1 working day, please pay attention to the email with the suffix “@isp-home.com”.